Why is Copper the Ideal Metal for Shaped Charge Penetrators?

Copper's unique properties make it the ideal choice for shaped charge penetrators, outperforming other soft metals under extreme pressures.

In the construction of shaped charge penetrators, copper has emerged as the metal of choice due to its exceptional physical properties and performance characteristics.

This choice is a result of a careful consideration of the ideal material for the task at hand.

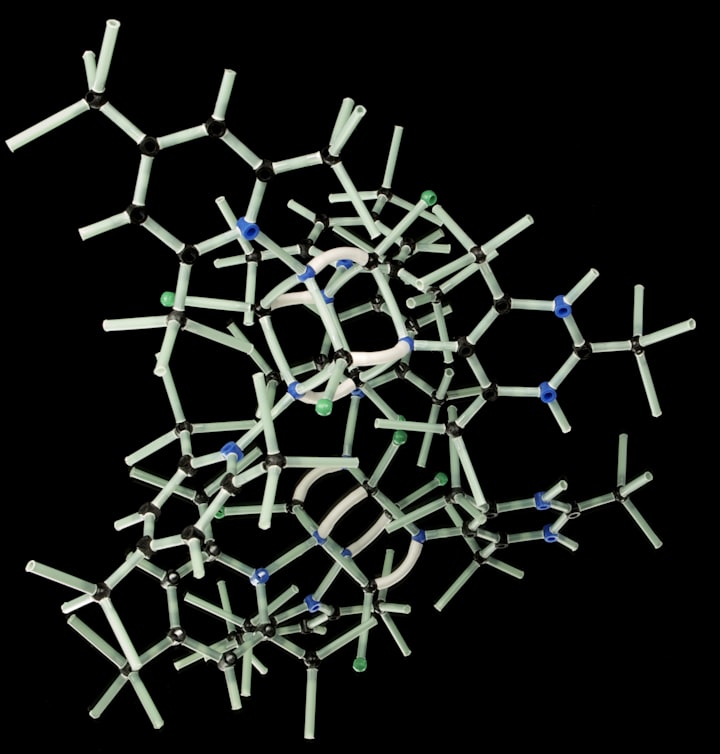

Ductility and Flow

Copper's exceptional ductility allows it to deform without truly melting under high-pressure conditions.

This property is crucial for the formation of shaped charge penetrators, as it enables the metal to undergo extreme deformation and maintain its integrity.

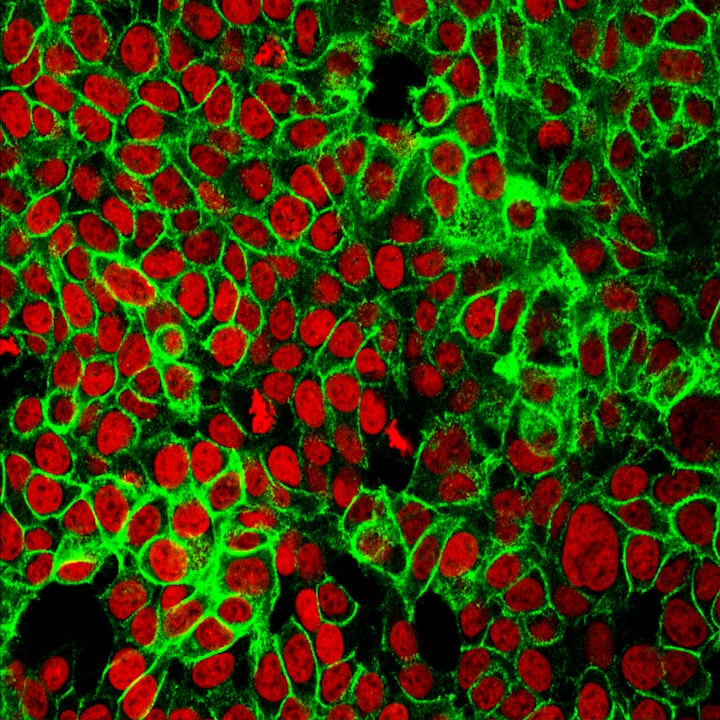

Heat Conductivity

One key attribute that sets copper apart is its high heat conductivity.

When subjected to an explosive blast, copper heats up rapidly, contributing to its penetration capabilities.

This rapid heating further enhances the material's performance in the shaped charge penetrator.

Work Hardening

Perhaps the most valuable property of copper in this context is its ability to work harden.

Even as it deforms and flows under pressure, copper retains its hardness, allowing it to maintain its structural integrity at the high velocities and pressures seen in shaped charge penetrators.

The Use of Other Soft Metals

While other soft metals like lead may seem like plausible alternatives, they lack the combination of ductility, heat conductivity, and work hardening that make copper so well-suited for this application.

Understanding High Pressures

It’s important to note that at the extreme pressures involved in shaped charge penetrators, materials can exhibit unconventional behaviors.

Copper's ability to flow without truly melting, coupled with its resilience to work hardening, make it the most suitable choice for these demanding applications.

Exploring the Use of Other Metals

While copper has been the metal of choice, ongoing research continues to explore the potential of other materials, such as tantalum and tungsten, in shaping charge penetrators.

These materials offer unique physical properties that may bring further advancements in the field.