Why are Stirling Engines Not More Widely Used?

Discover why Stirling engines are not widely used despite their potential to capture thermal energy efficiently.

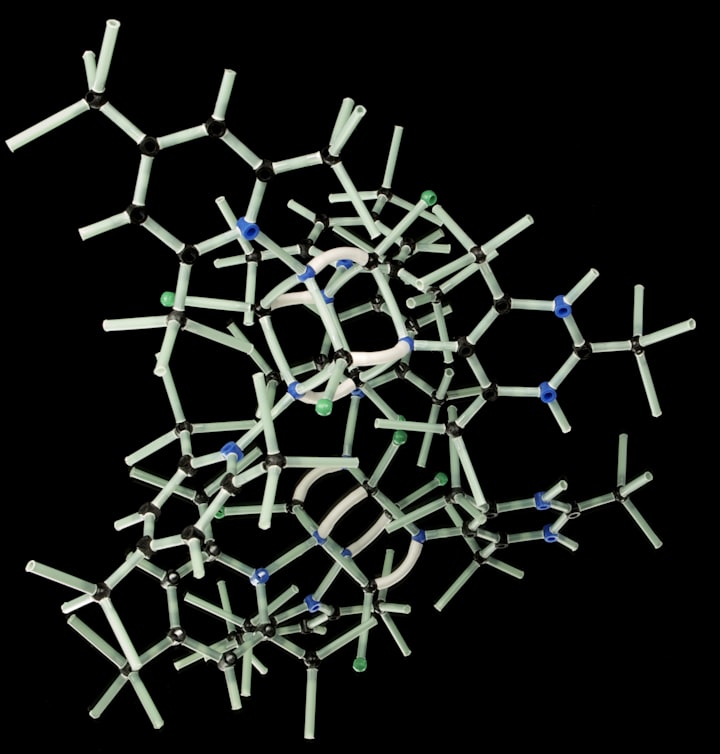

Stirling engines are renowned for their capacity to convert temperature differentials into mechanical work.

However, the full extent of their potential remains largely untapped.

The Limitations of Small Energy Differentials

Stirling engines often prove impractical for capturing energy from small differentials due to their relatively low energy output.

The costs involved in setting up and maintaining these engines far outweigh the energy they produce, making them inefficient for such applications.

Challenges in Power Plant Cooling Systems

In the context of power plants, effective waste heat dissipation is crucial for averting catastrophic events.

Integrating Stirling engines into these systems presents significant challenges, as they can disrupt the vital cooling process and compromise the overall efficiency of the entire system.

Efficiency Comparison

When it comes to harnessing substantial energy differentials, other more efficient engines and turbines are typically preferred over Stirling engines.

The market tends to favor options that offer better performance and cost-effectiveness.

Environmental Considerations

While Stirling engines have their uses, they may not always be the most environmentally friendly choice.

In specific instances, alternative technologies are considered more sustainable and environmentally friendly for thermal energy capture.

Future Perspectives

As technology continues to evolve, there may come a time when Stirling engines find their niche in specific energy capture applications.

With advancements in materials and engineering, these engines could become more viable for a broader range of thermal differentials.